Knowledge Vault

Enclosure Type Descriptions for Non-Hazardous Locations

In North America, UL, CSA, and NEMA are the commonly recognized standards organizations. Their ratings are based on similar application descriptions and expected performance. UL and CSA both require enclosure testing by qualified evaluators in their certified labs. They also send site inspectors to make sure a manufacturer adheres to prescribed manufacturing methods and material specifications. NEMA, on the other hand, does not require independant testing and leaves compliances up to the manufacturers.

North American enclosure rating systems also include a 4X rating that indicates corrosion resistance. This rating is based on the enclosure's ability to withstand prolonged exposure to salt water spray.

| Enclosure Type | UL | CSA | NEMA |

|---|---|---|---|

| Outdoor - Type 4 | Either indoor or outdoor use to provide a degree of protection against falling rain, splashing water and hose-directed water; undamaged by the formation of ice on the enclosure. | Indoor or outdoor use; provides a degree of protection against rain, snow, windblown dust, splashing and hose-directed water; undamaged by the external formation of ice on the enclosure. | Enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against windblown dust and rain, splashing water and hose directed water; undamaged by the formation of ice on the enclosure. |

| Outdoor - Type 4X | Either indoor or outdoor use to provide a degree of protection against falling rain, splashing water and hose-directed water; undamaged by the formation of ice on the enclosure; resists corrosion. | Indoor or outdoor use; provides a degree of protection against rain, snow, windblown dust, splashing and hose-directed water; undamaged by the external formation of ice on the enclosure; resists corrosion. | Enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing water and hose-directed water; undamaged by the formation of ice on the enclosure. |

| Indoor - Type 12 | Indoor use to provide a degree of protection against dust, dirt, fiber flyings, dripping water and external condensation of noncorrosive liquids. | Indoor use; provides a degree of protection against circulating dust, lint, fibers and flyings; dripping and light splashing of non-corrosive liquids; not provided with knockouts. | Enclosures are intended for indoor use primarily to provide a degree of protection against dust, falling dirt and dripping noncorrosive liquids |

| Indoor - Type 12K | Indoor use to provide a degree of protection against dust, dirt, fiber flyings, dripping water and external condensation of noncorrosive liquids. | Indoor use; provides a degree of protection against circulating dust, lint, fibers and flyings; dripping and light splashing of noncorrosive liquids; not provided with knockouts. | Enclosures with knockouts are intended for indoor use primarily to provide a degree of protection against dust, falling dirt and dripping noncorrosive liquids. |

| Indoor - Type 1 | Indoor use primarily to provide protection against contact with the enclosed equipment and against a limited amount of falling dirt. | General purpose enclosure. Protects against accidental contact with live parts. | Enclosures are intended for indoor use primarily to provide a degree of protection against contact with the enclosed equipment or locations where unusual service conditions do not exist. |

| Outdoor - Type 3 | Outdoor use to provide a degree of protection against windblown dust and windblown rain; undamaged by the formation of ice on the enclosure. | Indoor or outdoor use; provides a degree of protection against rain, snow and windblown dust; undamaged by the external formation of ice on the enclosure. | Enclosures are intended for outdoor use primarily to provide a degree of protection against windblown dust, rain and sleet; undamaged by the formation of ice on the enclosure. |

| Outdoor - Type 3R | Outdoor use to provide a degree of protection against falling rain; undamaged by the formation of ice on the enclosure. | Indoor or outdoor use; provides a degree of protection against rain and snow; undamaged by the external formation of ice on the enclosure. | Enclosures are intended for outdoor use primarily to provide a degree of protection against falling rain and sleet; undamaged by the formation of ice on the enclosure. |

| Outdoor - Type 3RX | Not specifically defined. | Not specifically defined. | Enclosures are intended for outdoor use primarily to provide a degree of protection against corrosion, falling rain and sleet; undamaged by the formation of ice on the enclosure. |

| Outdoor - Type 6 | Indoor or outdoor use to provide a degree of protection against entry of water during temporary submersion at a limited depth; undamaged by the external formation of ice on the enclosure. | Indoor or outdoor use; provides a degree of protection against the entry of water during temporary submersion at a limited depth. Undamaged by the external formation of ice on the enclosure; resists corrosion | Enclosures are intended for use indoors or outdoors where occasional submersion is encountered; limited depth; undamaged by the formation of ice on the enclosure. |

| Indoor - Type 13 | Indoor use to provide a degree of protection against lint, dust seepage, external condensation and spraying of water, oil and noncorrosive liquids. | Indoor use; provides a degree of protection against circulating dust, lint, fibers and flyings; seepage and spraying of non-corrosive liquids, including oils and coolants. | Enclosures are intended for indoor use primarily to provide a degree of protection against dust, spraying of water, oil and noncorrosive coolant. |

* Some enclosures may have multiple ratings. For instance:

- 4, 12 Outdoor use; able to be used indoors with modifications.

- 4X, 3RX Outdoor use; able to be used indoors with modifications.

- 4, 9 Can be used in both hazardous and non-hazardous locations.

Environmental Ratings for Enclosures Based on Ingress Protection

Ingess Protection (IP) Codes

| 1st Digit | Protection Against Foreign Objects | 2nd Digit | Protection Against Moisture |

| 0 | Not protected | 0 | Not protected |

| 1 | Protected against objects > than 50mm | 1 | Protected against dripping water |

| 2 | Protected against objects > than 12mm | 2 | Protected against dripping water when tilted up to 15N |

| 3 | Protected against objects > than 2.5mm | 3 | Protected against spraying water |

| 4 | Protected against objects > than 1.0mm | 4 | Protected against splashing water |

| 5 | Dust protected | 5 | Protected against water jets |

| 6 | Dust tight | 6 | Protected against heavy seas |

| --- | --- | 7 | Protected against the effects of immersion |

| --- | --- | 8 | Protected against submersion |

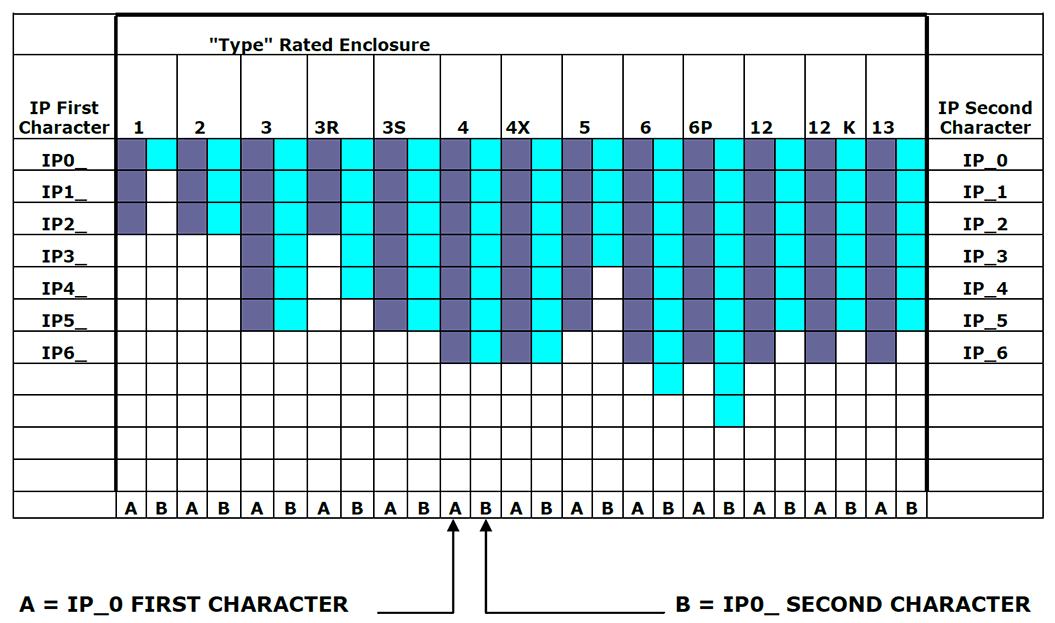

Comparison of IEC/IP Code and UL NEMA Ratings

IEC/IP Coding Defined

The following is a brief overview of the coding system described in the IEC publication 529 and the DIN standard number 4050. Both standards code the classification of degrees of protection provided by the enclosures.

The Meaning of the IP Code

The two code letters, IP (international protection) followed by the two reference numbers, indicate the level of environmental protection. The first reference number indicates the protection of solid objects. The second reference number indicates the protection level, if any, against water entry.

The following table shows how to convert the NEMA Ratings into IEC Classifications. However, the table cannot be used to convert IEC Classifications to NEMA Ratings.

Terminology

Corrosion-Resistant

Constructed to provide a degree of protection against exposure to corrosive agents such as salt spray. Type 3RX and 4X enclosures meet this requirement.

Damp Locations

Locations protected from weather and not subject to saturation with water or other liquids but subject to moderate degrees of moisture. Examples of such locations include partially protected locations under canopies, marquees, roofed open porches and like locations, and interior locations subject to moderate degrees of moisture, such as some basements, some barns and some cold-storage warehouses. See the indoor enclosure types and select a type rating that fits the specific application.

Dust-tight

Constructed so that circulating or airborne dust will not enter the enclosure under specified test conditions. Type 3, 4, 4X, 12, 12K and 13 enclosures meet this requirement.

Drip-tight

Not to be exposed to weather. Type 1, 12, 12K and 13 enclosures meet this requirement.

Oil-Resistant

Constructed so that oil will not interfere with successful operation of equipment. Type 12 and 13 enclosures meet this requirement.

Oil-tight

Constructed so that oil will not enter the enclosure under specified test conditions. Type 13 enclosures meet this requirement.

Outdoor

Constructed or protected so that exposure to the weather will not interfere with successful operation of equipment. Type 3, 3R, 4, 4X and 6 enclosures meet this requirement. These ratings can also be used indoors..

Rainproof

Constructed, protected or treated to prevent beating rain from interfering with the successful operation of the apparatus or result in wetting of live parts and wiring within the enclosure under specified test conditions. Type 3R and 3RX enclosures meet this requirement.

Rain-tight

Constructed or protected so that exposure to beating rain will not result in water entering the enclosure under specified test conditions. Type 3, 4, 4X and 6 enclosures meet this requirement.

Water-tight

Constructed so that moisture will not enter the enclosure when it is subjected to a stream of water under specified test conditions. Type 4, 4X and 6 enclosures meet this requirement.

Weatherproof

Constructed or protected so that exposure to the weather will not interfere with successful operation of the equipment. Rainproof, rain-tight or water-tight equipment can fulfill the requirements for weatherproof where varying weather conditions other than wetness, such as snow, ice, dust or temperature extremes, are not a factor.

Wet Locations

Installations underground or in concrete slabs or masonry in direct contact with the earth; in locations subject to saturation with water or other liquids, such as vehicle washing areas; and in unprotected locations exposed to weather. Use weatherproof enclosures with a type rating that fits the specific application.

Helpful Articles

- Steeline Manufacturing RSS Feeds

- Utilizing a Foam in Place Gasket for Custom Steel Enclosures

- Trusted Enclosure Engineering

- Stainless Steel Enclosure Box

- Enclosure Cooling Made Simple

- NEMA Electrical Enclosures

- Know Your Stainless-Steel Enclosure: Quarter Turn Latch

- Using the Foam in Place Gasket

- UL Approved

- Why Steeline Enclosures?

- Technical White Papers: What’s the CE Mark?

- Nema Rated Disconnect Enclosures

- Electric Enclosures for Electronics

- The Environment Determines the Enclosure

- NEMA Enclosure Industry Standard, Enclosures Built Right

- Sizing Your Enclosure

- Dallas Custom Enclosure Manufacturers

- Do You Need to Protect Electronics in Your Commercial Kitchen?

- Tell Us Where You Work, We’ll Help You Find the Right Enclosure

- SW Series Wall Mount Enclosures: Schaefer vs. Steeline

- Know Your Electrical Enclosure: Junction Boxes

- Corrosion Resistant Enclosures

- Control the Climate in Your Enclosure

- Steel Enclosures to Exact Specs

- Foam in Place Gasket Sealing Meets and Exceeds NEMA Standards

- Custom Steel Enclosures, Texas

- Standard, Pre-Engineered Enclosure Platforms

- UL 508, UL 50, and CSA Requirements

- Specialized Custom Enclosure Solutions

- Largest Steel Enclosure Facility in the Nation

- Freestanding Enclosures: Schaefer vs. Steeline

- Junction Boxes: Schaefer vs. Steeline

- Floor Mount Enclosures: Schaefer vs. Steeline

- Unexpected Applications for Electrical Enclosures

- Climate Control for Electrical Enclosures

- An Electrical Enclosure Box for Every Need

- Double Door Latch Stainless Steel Enclosures

- ISO 9000 Certified

- Foam in Place Gaskets for Enclosure Security

- Electrical Enclosures to Fit Your Needs

- Specializing in Type 4 and 4x Push Button Enclosures

- Why Stainless Steel?

- Meet Inspection Standards with Steeline

- A Cost-Effective Industrial Enclosure Solution

- What Enclosures Are Most Commonly Used For

- Using the New Hyper Gear Laser Processing Machine

- New Personnel at Steeline Enclosures

- Electrical Enclosures Manufactured in Dallas

- Wallmount Enclosures Online

- Cost Effective Alternatives for Industrial Enclosures

- Custom Metal Enclosures

- Type 4 & 4X Steeline Enclosures

- Stainless Steel Enclosures for Any Use

- Custom Metal Enclosures for Stainless Steel Enclosure Needs

- Control System Engineering – Your Manufacturer?

- Mechanical and Electronical – the SDC Series

- Cooling Features – Type 4 and 4x

- Freestanding Enclosure Uses

- Enclosures for Electrical Equipment

- Type 12 “SJB” Junction Boxes

- New Foam-in-Place Gasket

- Tough, Corrosion-Resistant Enclosures

- Steeline Superiority with Attention to Quality

- Nema Rated Electrical Enclosures

- Food & Beverage Electrical Enclosures Texas

- Cool Electronics within Steel Enclosures

- STEELINE “S-Series” WALL MOUNT ENCLOSURES

- Foam in Place Gasket & Sealing

- Disconnect Enclosures – Type 4X

- Choosing the Right Enclosure: How-to Guide

*Our team of experts are available to review and customize enclosure solutions to match your specific needs. If you do not see a system that filts your requirements, CONTACT US for a custom engineered system.